The Ultimate Guide to Work CMMS: Boost Maintenance Efficiency and Uptime

A work CMMS (Computerized Maintenance Management System) is a powerful software tool that centralizes maintenance data and streamlines work order management. By automating maintenance processes, a work CMMS enhances asset performance, reduces downtime, and improves overall operational efficiency in industries like manufacturing, construction, transportation, and more.

In this comprehensive guide, we’ll dive into what a work CMMS is, how it works, its benefits, and key considerations for selecting the right system for your business.

What Is a Work CMMS?

A work CMMS is software designed to optimize maintenance operations by centralizing information about physical assets—such as vehicles, machinery, plant infrastructure, and equipment—into one accessible database. Also known as a computerized maintenance management information system (CMMIS), it plays a critical role in industries that depend on robust asset management. Whether you’re in oil and gas production, power generation, or any asset-intensive field, a work CMMS helps maintain continuous operations and ensures reliable uptime.

How Does a Work CMMS Work?

At the core of every work CMMS is a robust database that organizes and stores essential asset information. This structured data supports several key functions:

1. Resource and Labor Management

- Employee Tracking: Monitor available technicians and track certifications.

- Task Assignment: Efficiently assign tasks, create crews, and manage shifts.

- Cost Management: Organize pay rates and track labor-related expenses.

2. Asset Registry

- Detailed Asset Information: Store manufacturer details, serial numbers, model data, and more.

- Performance Metrics: Monitor asset performance and downtime statistics.

- Documentation: Attach repair manuals, warranties, safety procedures, and even multimedia files for quick reference.

- IoT Integration: Connect meters, sensors, and IoT devices for real-time asset monitoring.

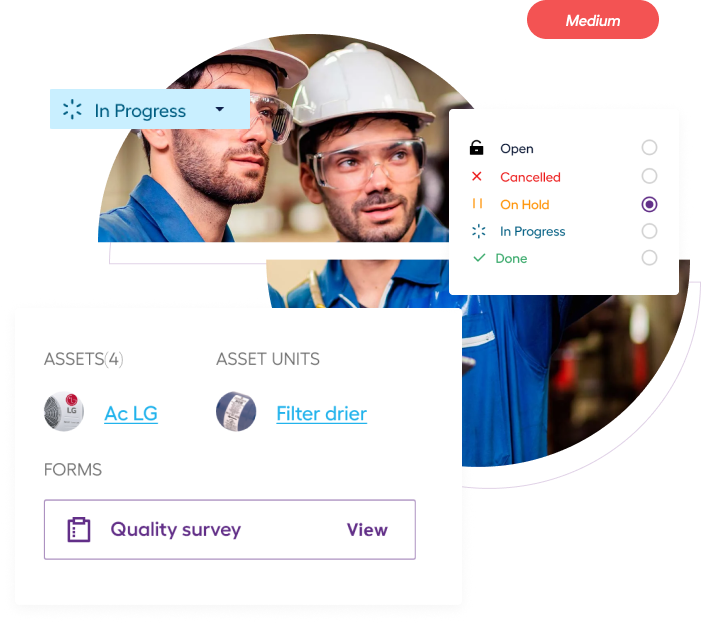

3. Work Order Management

- Comprehensive Work Orders: Generate and track work order details such as numbers, descriptions, priorities, and assigned personnel.

- Automation: Automate work order creation, reserve materials, and schedule shifts.

- Cost Tracking: Record planned versus actual costs and attach necessary documentation.

4. Preventive Maintenance

- Scheduled Maintenance: Automatically trigger work orders based on time intervals, usage, or event triggers.

- Asset Sequencing: Organize preventive work orders across multiple assets to minimize downtime.

5. Materials and Inventory Management

- Inventory Control: Distribute and reclaim MRO (Maintenance, Repair, and Operations) materials efficiently.

- Supplier Management: Track inventory costs and automate resupply orders.

6. Reporting, Analysis, and Auditing

- Custom Reports: Generate detailed reports on asset availability, materials usage, labor costs, and more.

- Data-Driven Decisions: Analyze trends to optimize maintenance strategies and support audit processes.

The Evolution of Work CMMS

Before the advent of CMMS, maintenance management was often a paper-driven or spreadsheet-based process, making centralized data visibility nearly impossible. Here’s a quick look at its evolution:

- 1960s: Early CMMS systems utilized punch cards and mainframe computers.

- 1970s: Technicians began using checklists, feeding data into the system at the end of shifts.

- 1980s-1990s: As computers became more affordable and connected, CMMS gained popularity among mid-sized and small businesses.

- 2000s to Today: With the rise of intranets, mobile devices, and now cloud-based solutions, the latest work CMMS systems offer enhanced functionality, faster implementations, and robust data security.

Work CMMS vs. EAM: Key Differences

While the terms CMMS and Enterprise Asset Management (EAM) are sometimes used interchangeably, there are important distinctions:

- Focus: A work CMMS typically centers on maintaining fixed asset availability and uptime through automated work order management and preventive maintenance.

- Scope: EAM expands on these capabilities by integrating across multiple sites, departments, and systems like ERP (Enterprise Resource Planning), offering a broader view of the asset lifecycle—including financial analysis, procurement, and compliance management.

- Integration: Modern EAM systems build upon CMMS foundations to deliver deeper collaboration and more strategic asset management.

Why Uptime Matters

Maintaining asset uptime is crucial for operational success. A reliable work CMMS minimizes unexpected downtime, ensuring that:

- Orders are met on time.

- Customer satisfaction is maintained.

- Asset longevity is extended, ultimately reducing repair costs.

Studies have shown that the longer equipment runs without major repairs, the more money businesses save, making uptime a key performance indicator for maintenance management.

Top Benefits of Using a Work CMMS

Implementing a work offers several tangible benefits:

- Enhanced Asset Visibility: Instant access to detailed asset histories, maintenance records, and performance data.

- Improved Workflow Transparency: Customized dashboards allow real-time monitoring of maintenance tasks and technician assignments.

- Automation & Efficiency: Automate routine tasks like ordering parts, scheduling preventive maintenance, and generating audit reports.

- Streamlined Processes: Centralized work order tracking and mobile access ensure coordinated efforts across teams.

- Effective Field Workforce Management: Simplify the coordination of internal and external maintenance teams.

- Preventive Maintenance: Shift from reactive repairs to proactive strategies, reducing the likelihood of asset failure.

- Consistent Procedures: Standardize maintenance protocols through centralized documentation and media storage.

- Compliance Management: Easily prepare for audits with tailored reports and detailed maintenance logs.

- Health, Safety, and Environmental Reporting: Monitor and report on safety metrics to maintain a secure working environment.

Selecting the Right Work CMMS Software

When choosing a work CMMS, consider the following factors:

- Data Management: Ensure the system can handle increasing amounts of data from various sources, including IoT devices.

- User-Friendliness: A system that requires minimal IT intervention is ideal for streamlined operations.

- Scalability: Look for cloud-based (SaaS) solutions that offer flexibility and the ability to scale with your business needs.

- Integration Capabilities: Choose software that integrates seamlessly with other critical systems, such as ERP and EAM.

- Cost Efficiency: A SaaS model can convert capital expenses into operational ones, reducing the need for extensive IT infrastructure.

The Push to SaaS in Work CMMS

Modern work CMMS solutions are increasingly offered as Software-as-a-Service (SaaS) models. Here’s why SaaS is transforming maintenance management:

- Cloud Flexibility: Scale data resources based on demand without large upfront hardware investments.

- Lower IT Dependency: SaaS platforms are easier to manage, requiring less in-house IT support.

- Continuous Upgrades: Cloud-hosted CMMS solutions benefit from regular updates, ensuring access to the latest features and security enhancements.

- Cost-Effective: Pay only for the services you need, making SaaS an attractive option for growing businesses.

Conclusion

A work CMMS is an indispensable tool for modern maintenance management. By centralizing data, automating routine tasks, and providing deep insights into asset performance, a work CMMS not only helps extend asset life but also drives overall operational efficiency. Whether you’re looking to improve workflow visibility, manage a mobile workforce, or transition to a cloud-based system, investing in the right work CMMS can lead to substantial long-term benefits.

Embrace the power of work CMMS technology and transform your maintenance operations today!

Optimize your maintenance processes with a work CMMS and experience enhanced asset uptime, streamlined operations, and significant cost savings. Subscribe to our newsletter for more insights on maintenance management solutions and the latest trends in work CMMS technology.

Feel free to share your thoughts or ask questions in the comments below!